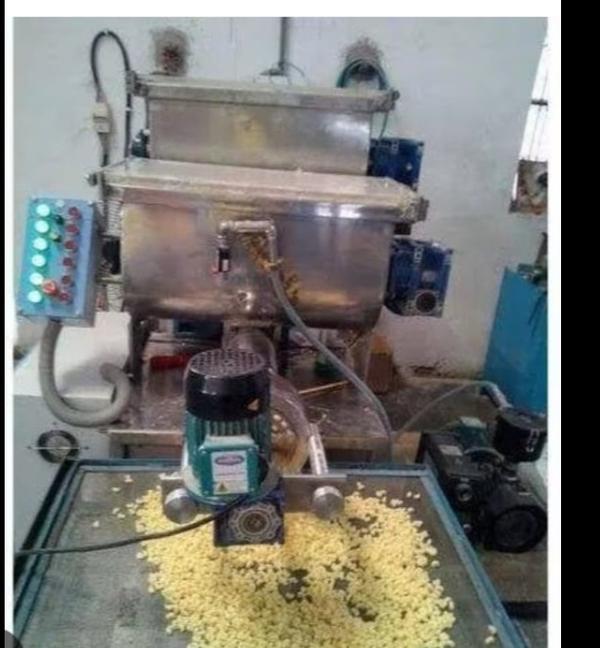

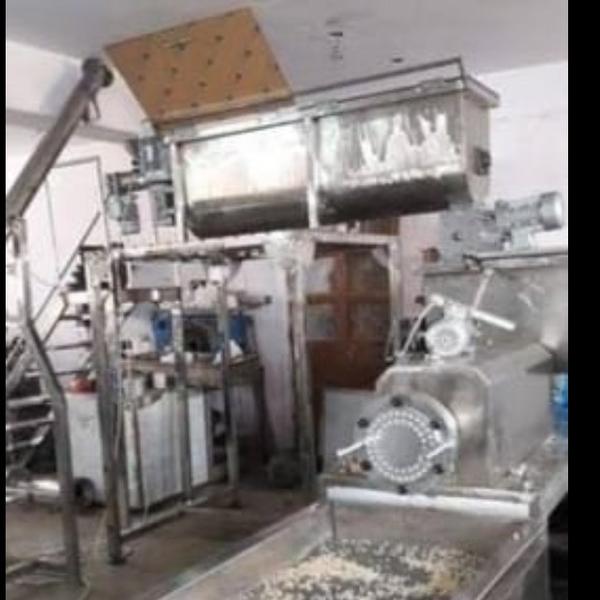

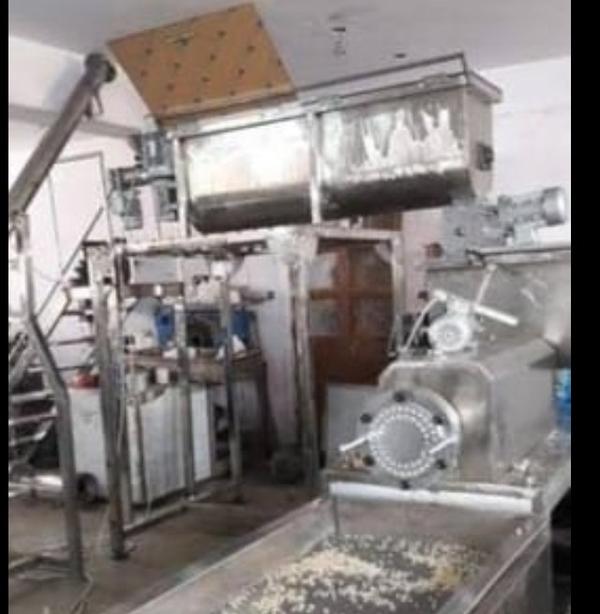

The production of macaroni and pasta on a commercial scale is a fascinating blend of traditional culinary art and modern engineering. A Pasta Macaroni Making Machine (or production line) is a sophisticated set of equipment designed to transform simple raw materials—mainly durum wheat semolina and water—into various shapes of pasta through a process of mixing, extrusion, and drying.1Here is a comprehensive breakdown of how these machines work, their components, and the industry standards governing them.1. The Core Technology: Single vs. Twin-Screw ExtrusionAt the heart of any macaroni machine is the extruder.2 Most modern industrial lines use Single-Screw Extrusion technology combined with a vacuum system.Vacuum System: This is critical. By removing air bubbles from the dough during the mixing phase, the machine ensures the final pasta is dense, has a vibrant yellow color, and doesn't crack during the drying process.The Screw: The screw pushes the dough forward through a barrel. The friction and pressure develop the gluten network, giving the pasta its 'al dente' structural integrity.2. The Production Process FlowA complete macaroni production line is usually automated to ensure consistency and hygiene.3 The process follows these five main stages:A. Raw Material Mixing (The Dosing System)The process begins with the precise measurement of flour (usually semolina) and water.4 High-end machines include automatic dosing pumps that maintain a moisture level of roughly 25% to 30%.B. Extrusion and ShapingThe dough is forced through a die (a mold).5 The shape of the die determines whether the machine produces macaroni, fusilli, penne, or shells.6Teflon Dies: Produce a smooth, shiny surface on the pasta.7Bronze Dies: Create a rougher, porous surface, which is preferred for high-end pasta as it helps sauces 'stick' to the noodle.8C. Pre-Drying (The Shaker)Immediately after being cut by a high-speed rotating blade, the pasta is damp and sticky. It passes through a vibrating pre-dryer (shaker) that uses hot air to dry the surface quickly, preventing the pieces from sticking together.9D. Final Drying (The Critical Stage)This is the most time-consuming part. The pasta enters a multi-layer drying oven.Temperature Control: If dried too fast, the pasta will crack (checking).10 If dried too slow, it could spoil or lose its shape.Moisture Reduction: The goal is to reduce moisture from ~30% down to a shelf-stable 12.5%.E. Cooling and PackagingBefore the pasta can be bagged, it must be cooled to room temperature in a cooling conveyor to prevent condensation inside the plastic packaging.3. Key Components of the MachineIf you are looking to invest in a macaroni machine, these are the technical components you must evaluate:ComponentFunctionMaterial RequirementFeeding HopperHolds the raw flour.Food-grade Stainless Steel (SUS304)Extrusion BarrelMaintains pressure and temperature.Water-cooled jacketed steelRotary CutterCuts the pasta to specific lengths.Frequency-controlled bladesDrying OvenRemoves moisture via heat.Multi-layer conveyor beltControl PanelManages speed, heat, and moisture.PLC Touch Screen (Delta/Siemens)4. Technical Specifications (Sample Data)For a medium-scale industrial machine, the specifications typically look like this:Production Capacity: 100kg/h to 500kg/h.Total Power: $50kW$ to $120kW$ (depending on the heating method).Required Space: A full line usually requires a length of 15 to 22 meters.Labor: 1–2 operators are needed to monitor the PLC system.5. Maintenance and HygieneBecause pasta is a food product, the machine must meet strict HACCP (Hazard Analysis and Critical Control Points) standards.Cleaning: The extrusion screw and dies must be cleaned after every shift to prevent dough from hardening and harboring bacteria.Lubrication: Use only food-grade lubricants for the mechanical gears.Material: Ensure all parts contacting the food are Stainless Steel 304, which resists corrosion from the moisture in the dough.6. Why Invest in a Macaroni Machine?The global pasta market continues to grow because it is a low-cost, high-shelf-life staple food.Versatility: By simply changing the die (which takes about 15 minutes), one machine can produce over 20 different shapes of pasta.Automation: Modern machines reduce human error, leading to a uniform product that looks professional on supermarket shelves.11High ROI: The raw materials (flour and water) are inexpensive compared to the retail price of packaged pasta.ConclusionA Pasta Macaroni Making Machine is a significant investment that combines mechanical pressure, thermal dynamics, and culinary science. Whether you are looking at a small artisanal extruder or a massive 1000kg/h industrial line, the key to quality lies in the vacuum extrusion and the precision of the drying cycle.