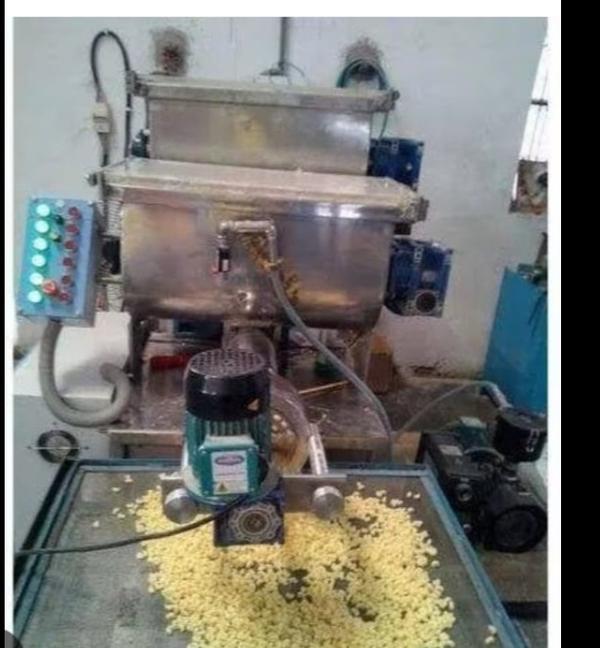

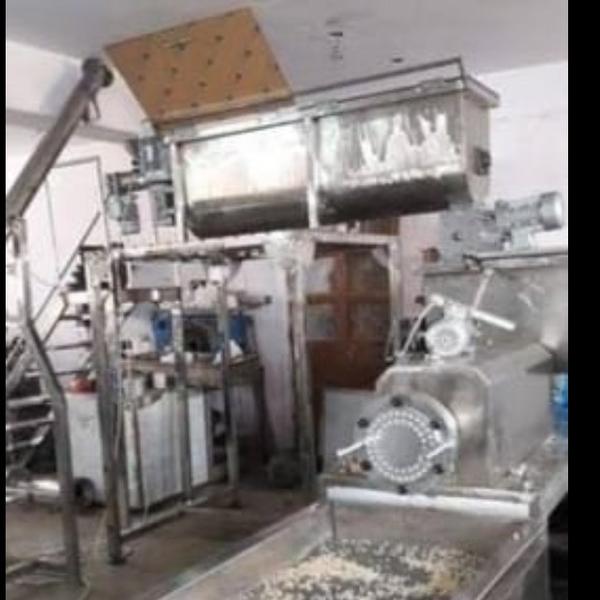

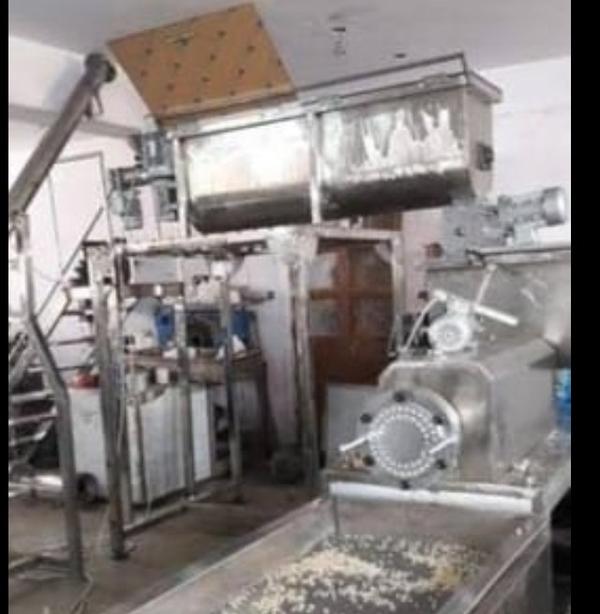

The production of macaroni at scale is a fascinating blend of culinary tradition and high-tech mechanical engineering. From the moment semolina flour enters the system to the final packaged product, a Macaroni Pasta Making Machine (or an industrial pasta extrusion line) must manage precise variables of moisture, pressure, and temperature.Here is an in-depth look at how these machines function, the technology behind them, and the industrial standards required to produce the perfect 'al dente' noodle.1. The Core Components of a Pasta MachineAn industrial macaroni line is not a single machine but a synchronized series of modules. To understand the process, we must look at the primary sections:Dosing and Mixing System: This is where the magic begins. Precise ratios of durum wheat semolina, water, and sometimes additives (like spinach or tomato powder) are measured.The Vacuum Extrusion Chamber: Unlike home pasta making, industrial machines often operate under a vacuum. This removes air bubbles from the dough, resulting in a more translucent, vibrant color and a stronger structural integrity that won't fall apart when boiled.The Screw and Barrel: A high-torque screw pushes the dough forward, kneading it into a perfectly homogenous 'plastic' state.The Die and Cutter: The die determines the shape (elbow, spiral, penne). As the pasta emerges, a high-speed rotating blade cuts it to the desired length.2. The Step-by-Step Production ProcessRaw Material PreparationQuality macaroni starts with Durum Wheat Semolina. This flour has a high protein content and gluten strength. The machine’s feeding system uses gravitational or pneumatic conveyors to move the flour into a centrifugal mixer.Extrusion: The Heart of the MachineOnce the dough reaches the right consistency (usually around 30-32% moisture), it enters the extrusion screw.Pressure Management: The machine generates pressures up to 100 bar to force the dense dough through the dies.Temperature Control: Friction generates heat. If the dough gets too hot, the gluten is damaged. Modern machines use water-cooled jackets around the barrel to keep the dough below 50°C.Shaping the MacaroniThe 'elbow' shape characteristic of macaroni is achieved through a specific die design. One side of the extrusion hole is slightly restricted or angled, causing the pasta tube to curl as it exits.3. The Drying Phase: The Most Critical StepYou can’t just bag wet pasta; it would mold within days. Drying is the longest and most energy-intensive part of the process.StageDurationPurposePre-Drying (Shaking)5-10 MinsPrevents the macaroni from sticking together immediately after cutting.Main Drying2–8 HoursSlowly reduces moisture from 30% down to roughly 12.5%.Stabilization1-2 HoursAllows the internal and external moisture levels to equalize to prevent cracking (checking).Modern machines use High-Temperature (HT) or Very High-Temperature (VHT) drying cycles. By drying at temperatures above 80°C, the machine can shorten production time and improve the cooking quality of the pasta.4. Technical Specifications to ConsiderIf you are looking to acquire or study these machines, these are the technical benchmarks:Production Capacity: Small-scale machines produce 30–50 kg/h, while massive industrial lines can exceed 6, 000 kg/h.Material Construction: To meet food safety standards (HACCP), all parts in contact with food must be AISI 304 or 316 Stainless Steel.Automation: High-end models feature PLC (Programmable Logic Controller) touchscreens that allow operators to save 'recipes' for different pasta shapes, adjusting screw speed and drying temperatures automatically.5. Maintenance and HygieneBecause pasta dough is organic and moist, these machines are breeding grounds for bacteria if not cleaned properly.CIP (Clean-In-Place) Systems: Many modern machines have automated washing cycles for the mixing basins.Die Maintenance: Dies are often coated with Teflon (for smooth, shiny pasta) or made of Bronze (for a rougher texture that holds sauce better). These require specialized ultrasonic cleaning baths to remove hardened dough from the intricate crevices.6. Why Invest in a Macaroni Machine?The global pasta market is resilient. Macaroni is a shelf-stable, affordable carbohydrate with high demand in both retail and 'instant meal' sectors. For a producer, the machine offers:Consistency: Every noodle is the same length, thickness, and weight.Versatility: By simply changing the die (which takes about 15 minutes), the same machine can produce fusilli, penne, or rigatoni.Scalability: Automated lines reduce labor costs significantly, requiring only 1-2 technicians to oversee a massive output.Summary of the WorkflowFeeding: Semolina + Water.Mixing: Homogenizing the dough.Vacuuming: Removing air for better color/strength.Extrusion: Shaping through the die.Cutting: Precision length control.Pre-Drying: Surface hardening.Drying/Cooling: Final moisture removal.Packaging: Ready for the shelf.