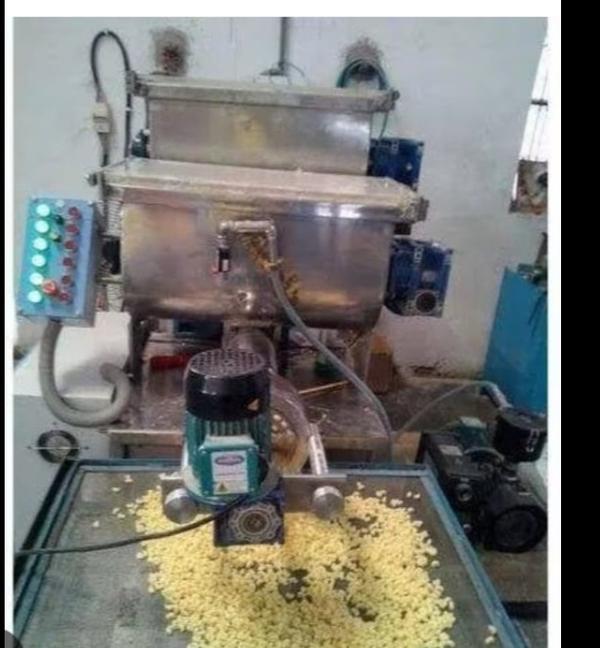

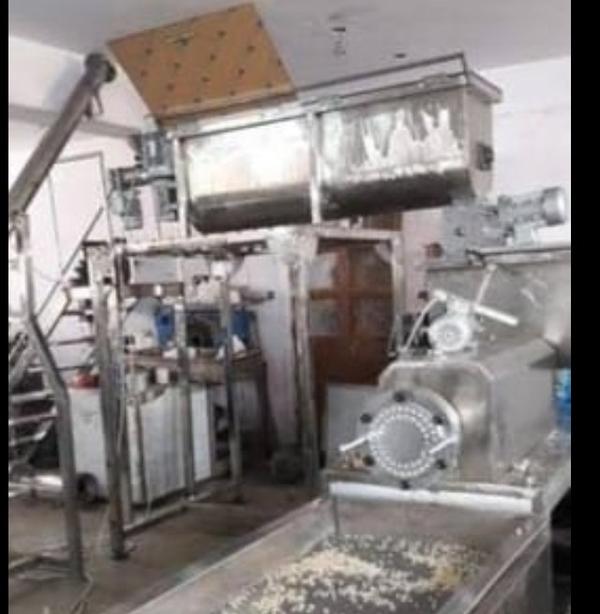

The production of macaroni, vermicelli, and various pasta shapes has evolved from a labor-intensive kitchen craft into a sophisticated industrial process. At the heart of this transformation is the Macaroni Vermicelli Pasta Making Machine, a versatile piece of engineering designed to handle everything from dough mixing to final extrusion.This guide explores the technical specifications, operational mechanisms, and business advantages of investing in a high-quality pasta production line.1. Introduction to Pasta Extrusion TechnologyModern pasta machines generally utilize single-screw or twin-screw extrusion technology. These machines are designed to process raw materials—typically semolina (durum wheat), all-purpose flour, or even alternative grains like corn and rice—into consistent shapes.The primary goal of the machine is to create a product that maintains its structural integrity during boiling while offering the desired 'al dente' texture.2. The Production Process: Step-by-StepA complete pasta making line is an integrated system where several components work in harmony.A. Mixing and DosingThe process begins in the High-Speed Mixer. Here, flour is combined with water (and sometimes eggs or spinach puree for color). The moisture content is critical; typically, pasta dough requires a moisture level of 25% to 30%.Vacuum Mixing: High-end machines feature vacuum mixing chambers. By removing air from the dough, the machine prevents oxidation and ensures the final pasta has a vibrant yellow color and no tiny air bubbles, which can cause breakage.B. Extrusion and ShapingOnce the dough is uniform, it is pushed through the Extruder.The Screw: A rotating screw compresses the dough and pushes it toward the die.The Die (Molds): The 'Die' is a metal plate with specific cut-outs. Depending on the die used, the machine can produce:Macaroni: Using a circular die with a center pin.Vermicelli: Using a plate with hundreds of tiny holes.Fusilli/Penne: Using specialized rotating cutters.C. CuttingAs the pasta emerges from the die, a Rotary Cutter with adjustable speeds slices the pasta to the desired length. For long vermicelli, the strands are often draped over poles, whereas short-cut macaroni is sliced immediately at the die face.D. Pre-Drying and DryingFreshly extruded pasta has high moisture.Shaker Pre-dryer: Vibrates the pasta to prevent sticking and removes surface moisture.Continuous Drying Oven: The pasta travels through multiple layers of conveyor belts in a temperature-controlled environment. Slow drying is essential to prevent 'checking' (cracking).3. Key Features of Modern MachinesIf you are looking to purchase or upgrade, these are the technical benchmarks to consider:FeatureDescriptionBenefitMaterialFood-grade Stainless Steel (SUS304)Ensures hygiene and prevents rust.PLC ControlTouchscreen interface (Siemens/Delta)Precise control over speed and temperature.Vacuum SystemIntegrated vacuum pumpImproves density and shelf life.Cooling SystemWater-cooled barrelsPrevents the dough from 'cooking' inside the machine.4. Technical Specifications (Sample 100-150kg/hr Line)To give you an idea of the physical and electrical requirements for a medium-scale setup:Total Power: $50text{ kW}$ to $70text{ kW}$ (including drying).Floor Space: Approximately $15text{m} times 3text{m}$.Manpower: 2–3 operators.Output Range: Customizable from $100text{ kg/h}$ up to $2, 000text{ kg/h}$ for large factories.5. Maintenance and HygienePasta machines deal with wet flour, which can become a breeding ground for bacteria if not cleaned properly.CIP (Clean-In-Place): Many modern machines allow for easy disassembly of the screw and die for daily pressure washing.Lubrication: High-torque gearboxes require regular oil changes to handle the immense pressure of extrusion.6. Market Potential and ROIInvesting in a macaroni and vermicelli machine is highly lucrative in today’s market for several reasons:Long Shelf Life: Dried pasta can stay shelf-stable for 1–2 years.Versatility: With one machine and five different dies, you can market five different products.Value Addition: The cost of raw semolina is significantly lower than the retail price of branded pasta, offering high profit margins.Pro Tip: Consider the 'Gluten-Free' market. By using a twin-screw extruder, you can process rice and corn flour, which are traditionally harder to shape, allowing you to tap into the premium health-food segment.7. ConclusionThe Macaroni Vermicelli Pasta Making Machine is more than just a kitchen appliance; it is a precision industrial tool. Whether you are a small entrepreneur starting a boutique pasta brand or a large-scale manufacturer, understanding the nuances of vacuum extrusion and controlled drying is the key to producing world-class pasta.The right machine reduces waste, ensures uniform cooking times for the consumer, and scales with your business growth.