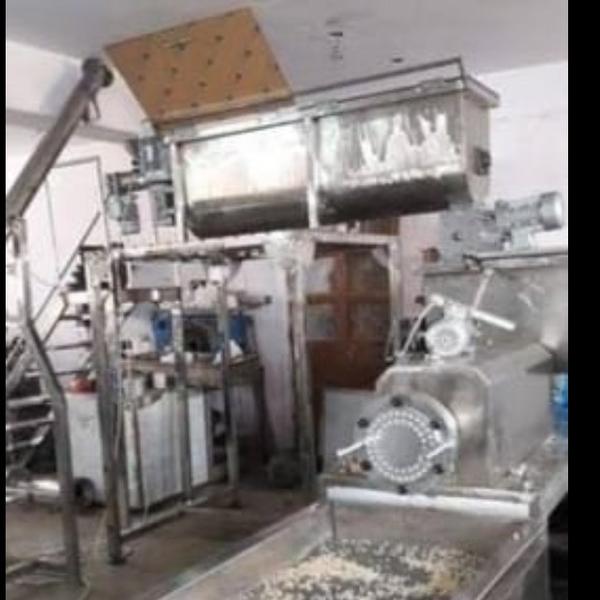

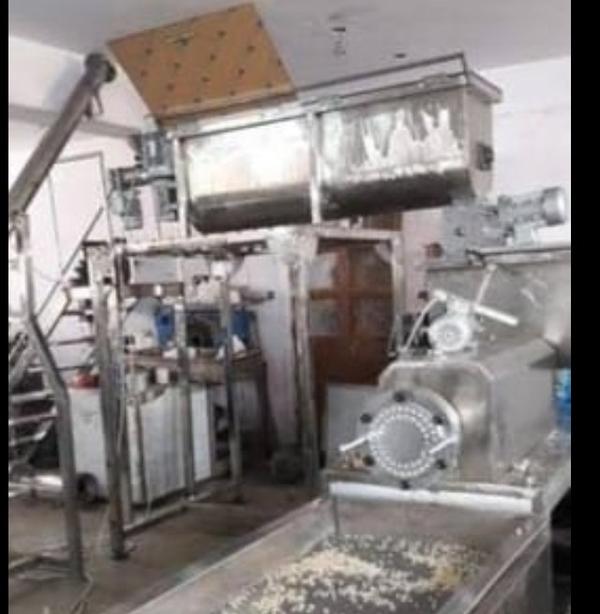

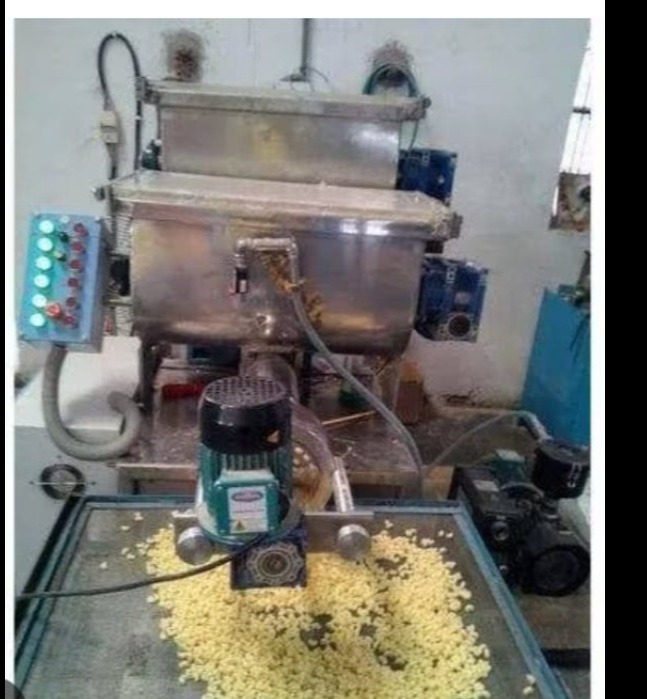

If you’re looking to dive into the world of industrial food production or simply want to understand the mechanics behind your favorite comfort food, the Pasta Macaroni Machine is a marvel of food engineering.From small countertop extruders to massive industrial lines stretching across factories, these machines have revolutionized how the world eats. Here is a comprehensive guide to everything you need to know about macaroni production technology.1. What is a Pasta Macaroni Machine?At its core, a macaroni machine is an extrusion system. Unlike handmade pasta which is rolled and cut, macaroni requires high pressure to force dough through a shaped die. This process creates the hollow tubes, elbows, and shells we know and love.The Modern EvolutionModern machines are no longer just 'mixers.' They are fully automated systems that handle:Raw material intake (Semolina, flour, water).Vacuum mixing (To prevent air bubbles and oxidation).Extrusion (The shaping process).Pre-drying and Cooling (To ensure the pasta doesn't stick).2. The Core Components of the MachineTo understand the 1, 000-word scope of these machines, we have to look at the 'anatomy' of a high-end industrial line.A. The Mixing SystemHigh-quality pasta starts with a uniform dough. The machine uses a paddle mixer to combine semolina with water. Many premium machines use Vacuum Mixing Technology. By removing air during the mixing phase, the pasta achieves a more vibrant yellow color and a denser texture that holds up better during boiling.B. The Extruder (The Heart)This is where the magic happens. A large screw (auger) pushes the dough toward the die head.The Die: A brass or Teflon-coated plate with holes. Brass dies create a rougher texture (perfect for holding sauce), while Teflon dies create a smooth, shiny finish.The Cutter: A rotating blade sits at the face of the die, spinning at specific speeds to cut the pasta to the desired length (short for macaroni, long for rigatoni).C. The Drying SystemPasta comes out of the machine with about 30% moisture. If you packaged it immediately, it would mold.Pre-dryer (Shaker): Vigorously shakes the pasta to prevent sticking.Main Dryer: Uses controlled humidity and temperature to slowly bring moisture down to roughly 12%.3. Types of Macaroni MachinesDepending on your scale of operation, machines fall into three categories:Machine TypeCapacityBest ForManual/Countertop1–5 kg/hrSmall cafes, home enthusiasts.Commercial Standalone30–100 kg/hrRestaurants, artisanal pasta brands.Industrial Continuous Line200–2, 000 kg/hrLarge-scale grocery supply chains.4. The Production Process (Step-by-Step)Dosing: Precise ratios of flour and water (and sometimes eggs or spinach powder) are fed into the hopper.Hydration: The flour particles absorb water.Compression: The auger compresses the dough, increasing the temperature slightly (too much heat ruins the protein, so many machines have water-cooling jackets).Extrusion: The dough is forced through the die.Cutting: An automated knife clips the tubes into 'elbows.'Dehydration: The pasta travels through a multi-layer drying oven.5. Key Features to Look ForIf you are in the market for a machine, these specs are non-negotiable:Stainless Steel Construction: Must be food-grade (SUS304) for hygiene and longevity.Variable Speed Control: Allows you to adjust the 'bite' and length of the pasta.Interchangeable Dies: A good machine should allow you to switch from macaroni to fusilli or penne in minutes.PLC Touchscreen: Modern industrial machines use digital interfaces to monitor temperature and pressure in real-time.6. Maintenance and CleaningBecause pasta dough is essentially 'glue' when it dries, cleaning is the most critical part of ownership.Die Soaking: Dies must be removed and soaked in water immediately after use to prevent the dough from hardening in the crevices.Auger Removal: The screw should be easily removable for deep cleaning to prevent bacterial growth.7. Why Invest in a Macaroni Machine?The ROI (Return on Investment) for these machines is high because the raw materials (flour and water) are inexpensive compared to the value of the finished, packaged product. Furthermore, the shelf life of dried macaroni (up to 2 years) makes it a very low-risk product for manufacturers compared to fresh foods.Pro Tip: If you're going for a 'premium' feel, look for a machine that supports low-temperature drying. While it takes longer (up to 24 hours), it preserves the nutritional integrity and flavor of the grain.