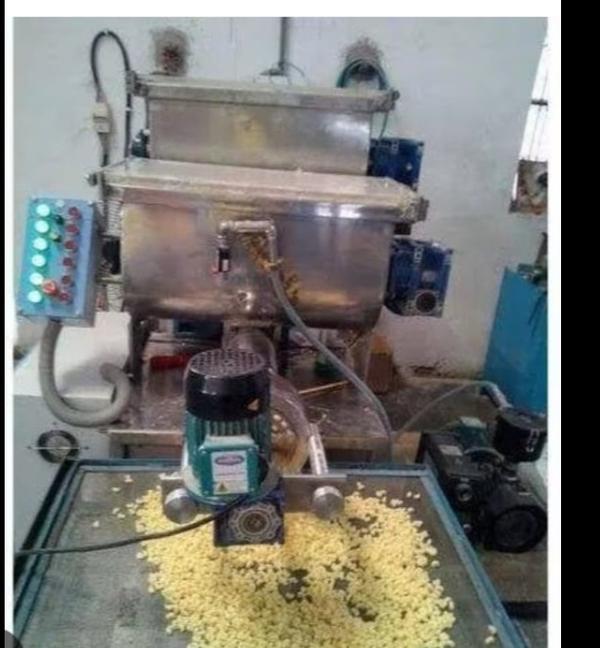

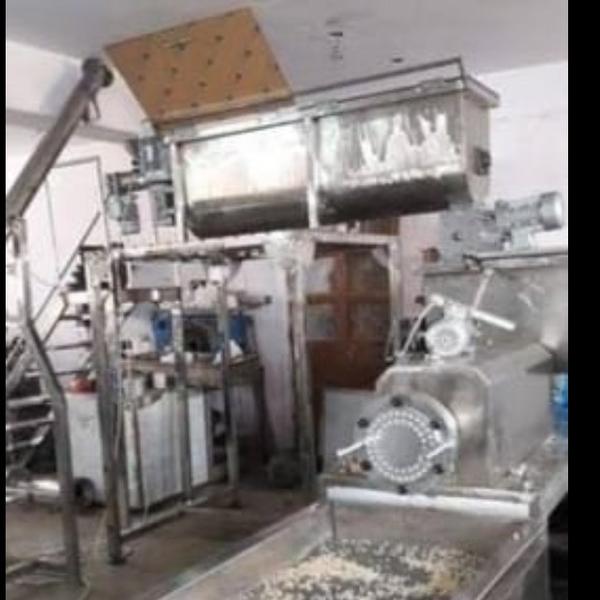

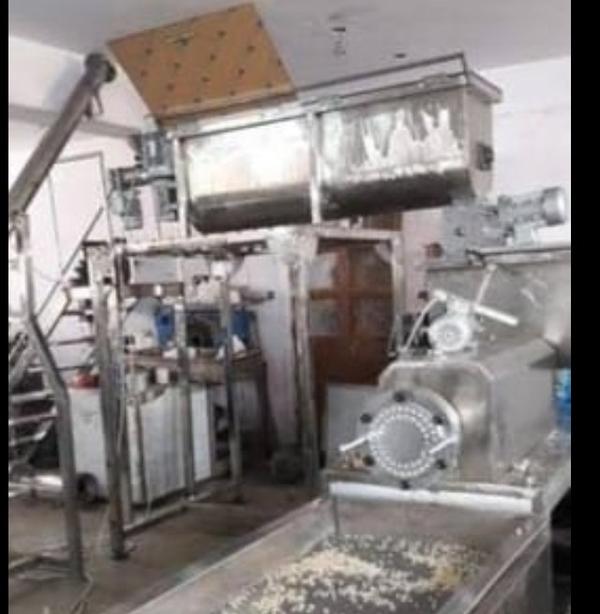

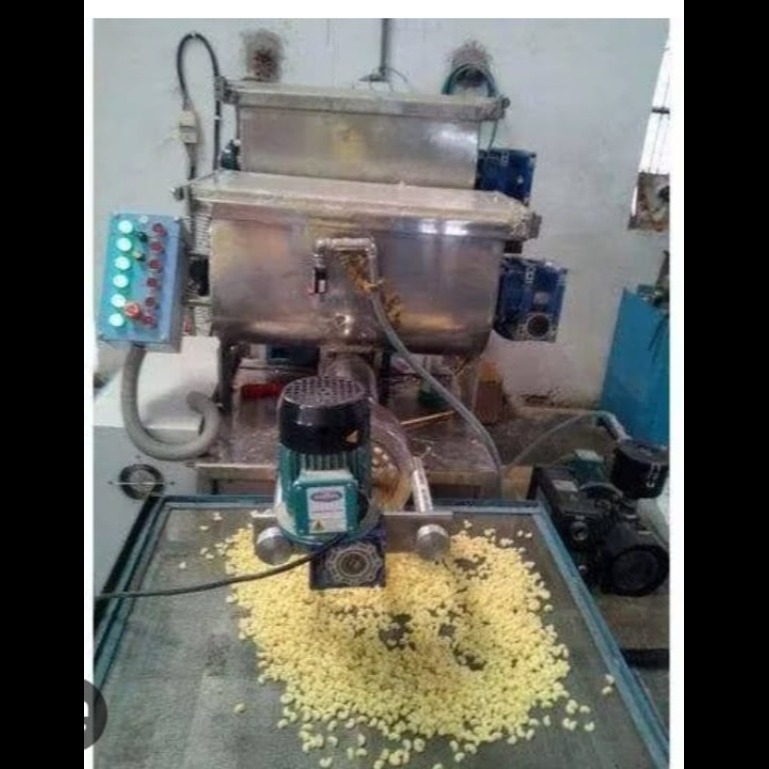

A Macaroni Pasta Making Machine is a sophisticated piece of industrial or kitchen equipment designed to transform raw ingredients—primarily semolina flour and water—into the iconic tube-shaped pasta we know as macaroni.1 Whether it’s a small countertop unit for a boutique bistro or a massive industrial line producing tons per hour, these machines rely on the principles of extrusion technology.2Below is a comprehensive breakdown of the components, processes, and types of macaroni making machines.1. The Core ComponentsTo understand how a machine turns powder into pasta, we have to look at its anatomy:Mixing System: This is where the magic begins. High-speed paddles blend flour, water, and sometimes eggs or vegetable purees.3 The goal isn't a smooth dough like bread, but rather a 'crumbly' consistency that is hydrated evenly.The Extruder Screw: This is a large, stainless steel screw (auger) that pushes the dough forward. As it moves, it compresses the dough, removing air bubbles to ensure the pasta is dense and won't fall apart during boiling.The Extrusion Die: This is a metal disc with specific cutouts.4 For macaroni, the die has circular holes with a 'pin' in the center to create the hollow tube.5The Cutting System: A rotating blade sits at the face of the die. By adjusting the speed of the blade, the machine determines the length of the macaroni (e.g., short elbows vs. long straight tubes).2. The Production Process: Step-by-StepA. Dosing and MixingIn industrial settings, vacuum mixers are often used.6 By removing air during the mixing stage, the machine prevents oxidation. This keeps the pasta’s color a vibrant yellow and prevents the finished product from becoming brittle.B. Extrusion and ShapingThe dough is forced through the die at high pressure.7 For 'elbow' macaroni, the die is designed to exert slightly more pressure on one side of the tube than the other, causing the pasta to curl as it emerges.C. Pre-Drying (The 'Shaking' Stage)Freshly extruded pasta is very sticky. Most machines immediately pass the macaroni through a trabatto (a vibrating pre-dryer). This uses hot air and vibration to dry the surface quickly, preventing the pieces from sticking together in the next stage.D. Final Drying and CoolingThe macaroni travels through a long drying tunnel. This is the most critical stage. If it dries too fast, the pasta will crack (checking); if it dries too slow, it may mold or lose its shape. The moisture content is typically brought down to about 12.5%.3. Types of Macaroni MachinesMachine TypeProduction CapacityBest ForManual/Electric Countertop1–5 kg/hrHome use, small cafesSemi-Industrial30–100 kg/hrArtisan pasta brands, restaurantsFully Automated Industrial Line500–2000+ kg/hrLarge-scale food manufacturing4. Key Features to Look ForIf you are considering investing in a macaroni machine, these technical aspects define quality:Stainless Steel Construction: Food-grade (304 or 316) stainless steel is non-negotiable for hygiene and longevity.8Water Cooling System: Extrusion generates friction heat.9 If the dough gets too hot (above 50°C), the protein structure breaks down. High-end machines use water-cooled jackets around the extrusion sleeve to keep the dough cool.Variable Speed Control: Using Frequency Inverters allows the operator to fine-tune the motor speed, which is essential when switching between different flour types (e.g., gluten-free vs. durum).10Die Material: * Teflon Dies: Produce smooth, shiny pasta.11Bronze Dies: Produce a rough, porous surface that helps pasta sauce 'stick' better—often preferred for premium brands.125. Maintenance and HygieneBecause pasta dough is a biological product, the machine must be cleaned thoroughly to prevent bacterial growth. Modern industrial machines often feature CIP (Clean-In-Place) systems, which flush the internal components with sanitizing solutions without requiring a full teardown.13Pro Tip: Always clean the extrusion dies immediately after use. Once pasta dough dries inside those tiny holes, it becomes hard as cement and can require hours of soaking or specialized ultrasonic cleaning to remove.6. The Future: Automation and AIModern macaroni machines are now integrating IoT (Internet of Things) sensors.14 These sensors monitor the humidity of the dough and the temperature of the extruder in real-time, automatically adjusting the water flow or screw speed to ensure every batch of macaroni is identical.15