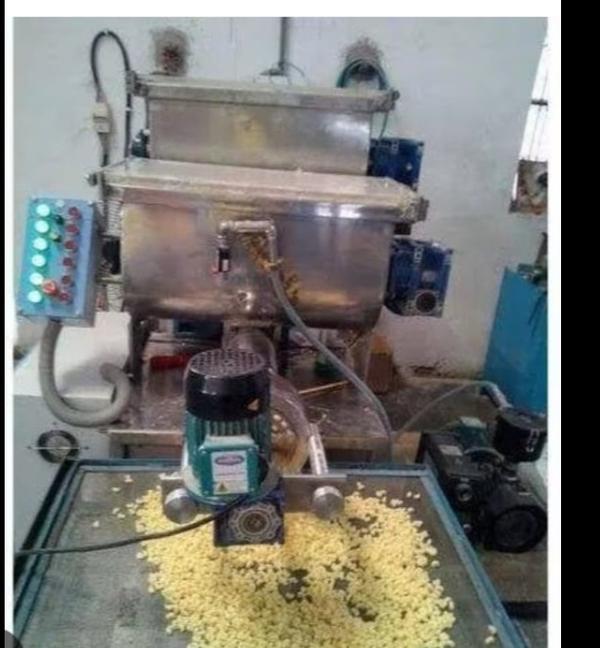

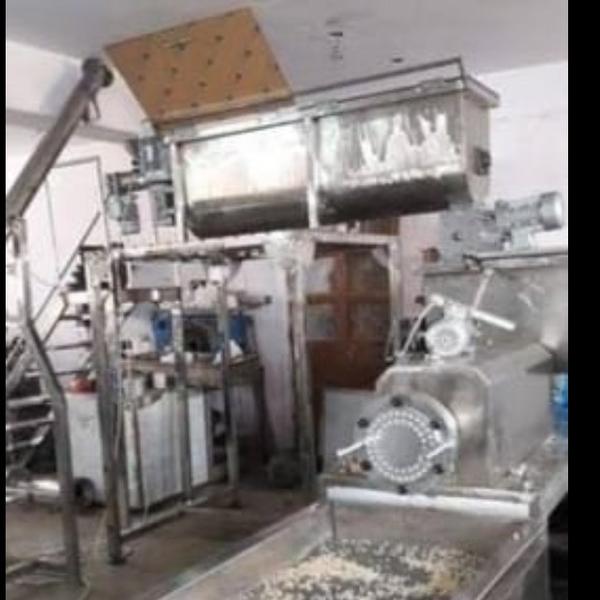

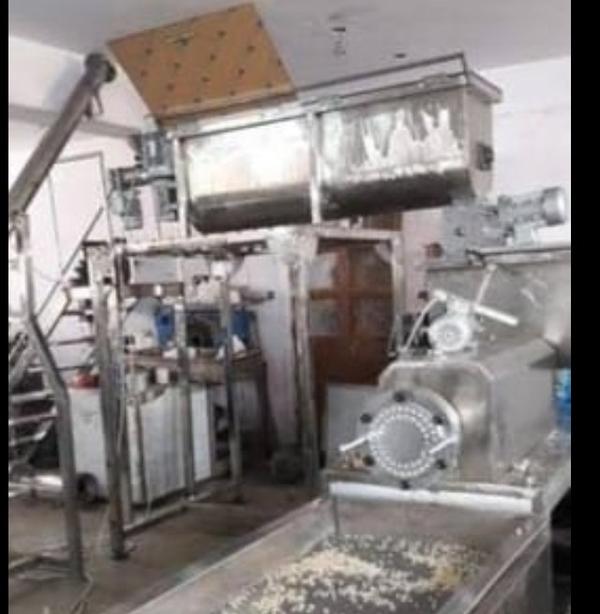

The Complete Guide to Agarbatti Making Machines: Technology, Business, and BenefitsThe incense stick, or agarbatti, holds a sacred and cultural place in many parts of the world, particularly in Asia. What was once a traditional cottage industry driven by hand-rolling has evolved into a high-tech manufacturing sector. The backbone of this transformation is the Agarbatti Making Machine.Whether you are an aspiring entrepreneur or a curious reader, understanding the mechanics, types, and business potential of these machines is the first step toward entering this multi-million dollar global market.1. Understanding the Mechanics: How It WorksAn agarbatti making machine is an automated or semi-automated system designed to coat a bamboo stick with a combustible paste. This paste usually consists of charcoal powder, wood flour (jigat), and binding agents.The basic process involves:Hopper Feeding: The raw incense powder mix is loaded into a hopper.Stick Feeding: Bamboo sticks are fed into the machine, either manually or via an automatic feeder.Extrusion: The machine uses high pressure to extrude the paste onto the stick as it passes through a die.Collection: The finished 'raw' sticks are collected on a tray, ready for drying and scenting.2. Types of Agarbatti Making MachinesTo choose the right machine, you must understand the different levels of automation available in the market today.A. Manual MachinesThese are hand-operated or pedal-operated machines. They are best suited for very small-scale home businesses or NGOs focused on rural employment. While low in cost, they require significant physical labor and offer low production volume.B. Semi-Automatic MachinesIn these models, the stick feeding is often manual, but the extrusion and coating are motorized. They offer a middle ground for those with a limited budget who still want a decent output (around 15–30 sticks per minute).C. Fully Automatic MachinesThese are the industry standard for commercial production. They feature automatic stick feeders and high-speed extrusion.Speed: Can produce 150 to 300 sticks per minute.Consistency: Every stick is uniform in length and thickness.Labor Efficiency: One operator can often manage two or three machines simultaneously.D. High-Speed 'Rocket' MachinesThe latest innovation in the industry, these machines can exceed speeds of 400 sticks per minute. They are built with heavy-duty frames to minimize vibration and ensure long-term durability.3. Key Components of a Quality MachineWhen investing in a machine, pay close attention to these specific parts:Piston/Cylinder: The heart of the extrusion process. Hardened steel components last longer against the abrasive nature of charcoal powder.Motor: Look for a motor with a high copper content and a reputable brand name to ensure it can handle 8–10 hours of continuous operation.Sensor: High-end automatic machines use sensors to detect if a stick is jammed, preventing damage to the internal gears.Control Panel: Modern machines come with PLC (Programmable Logic Controller) systems to adjust speed and monitor output.4. Raw Materials RequiredA machine is only as good as the material you feed it. To produce high-quality agarbatti, you need:Bamboo Sticks: Usually 8, 9, or 12 inches in length.Premix Powder: A blend of charcoal powder, Jigat (bark powder used as a binder), and Kupam dust.Water: To create a dough-like consistency.Fragrance/Perfume: Added after the sticks are dried.DEP (Diethyl Phthalate): Used as a carrier oil for the fragrance.5. Why Invest? The Business AdvantagesThe global incense market is growing due to the rising popularity of aromatherapy, meditation, and spiritual practices.BenefitDescriptionLow Entry BarrierYou can start a small unit in a single room with a single phase power connection.High DemandAgarbatti is a consumable product; once used, the customer must buy more.ScalabilityYou can start with one machine and add more as your brand grows.Export PotentialThere is massive demand for high-quality organic incense in Europe and North America.6. Operational Challenges and MaintenanceWhile the machines are efficient, they are not 'set and forget.' Regular maintenance is vital:Daily Cleaning: Charcoal dust is invasive. If not cleaned daily, it can clog the motor and moving parts.Lubrication: Weekly oiling of the gears and pistons is necessary to prevent friction damage.Stick Quality: If your bamboo sticks are not uniform in thickness, they will jam the automatic feeder frequently.7. Setting Up Your Manufacturing UnitTo set up a professional unit, follow these steps:Space: A minimum of 200–500 sq. ft. is required for one machine, raw material storage, and drying racks.Power: Most automatic machines run on a 1HP to 2HP single-phase motor.Drying Area: Sticks must be dried (sun-dried or via a drying machine) before they can be scented.Licensing: Depending on your region, you may need a basic trade license or small-business registration (like Udyam in India).8. ConclusionThe Agarbatti Making Machine has revolutionized a traditional craft into a profitable industrial venture. By reducing human error and increasing production speed, these machines allow entrepreneurs to focus on what truly matters: brand building and fragrance innovation.Success in this business doesn't just come from owning the machine; it comes from the quality of your raw materials and the uniqueness of your scents. With the right machine and a solid marketing strategy, the humble incense stick can lead to a highly lucrative business.