Agarbatti Making Machine 1000 Words Containt

The Agarbatti (incense stick) industry has evolved from a traditional cottage craft into a high-tech manufacturing sector. With the global demand for fragrance products rising, the Agarbatti Making Machine has become the backbone of modern production.

This guide explores everything you need to know about these machines, from technical specifications to business advantages.

1. The Evolution of Agarbatti Production

For centuries, incense sticks were hand-rolled. While this preserved traditional methods, it limited volume and consistency. The introduction of automatic and semi-automatic machines changed the landscape by:

Increasing production speed by up to 10x.

Ensuring uniform thickness and length.

Reducing labor costs and physical strain on workers.

2. Types of Agarbatti Making Machines

Choosing the right machine depends on your budget, space, and target production volume.

A. Manual Agarbatti Machines

These are hand-operated or foot-pedal-driven.

Best for: Small scale/home-based startups.

Production: Low (approx. 10–20 sticks per minute).

Pros: Very affordable, no electricity required.

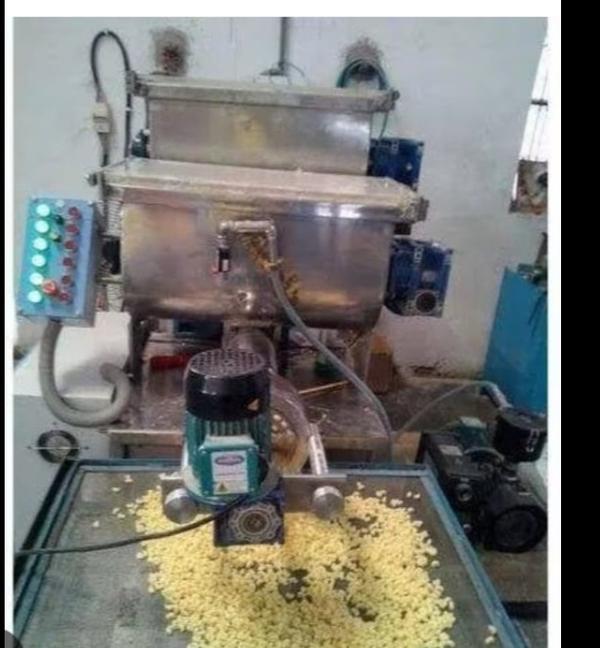

B. Semi-Automatic Machines

In these machines, the operator manually feeds the bamboo sticks into the feeder, but the machine handles the coating of the wet paste.

Best for: Micro-enterprises.

Pros: Better consistency than manual machines.

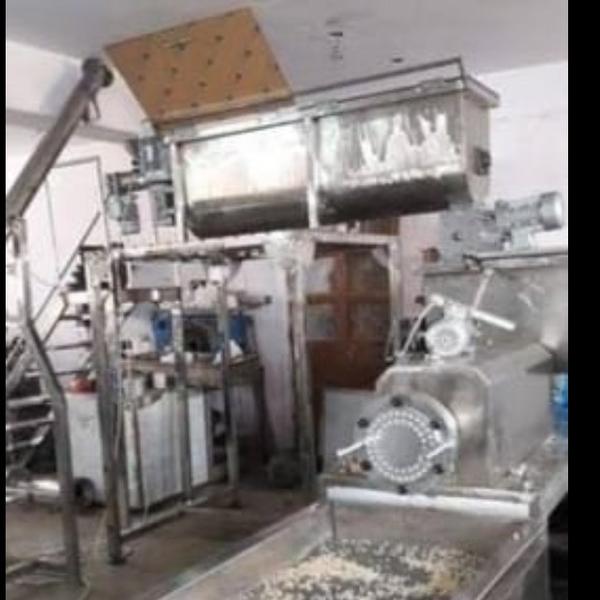

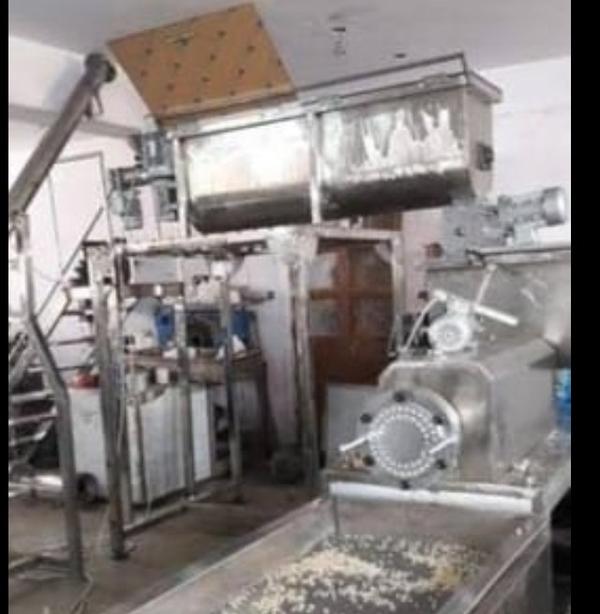

C. Fully Automatic High-Speed Machines

The industry standard. These machines feature an automatic stick feeder and a piston-press system.

Best for: Commercial manufacturing.

Production: 150 to 350+ sticks per minute.

Pros: Minimum human intervention, high ROI, and 24/7 operation capability.

3. Technical Components & Specifications

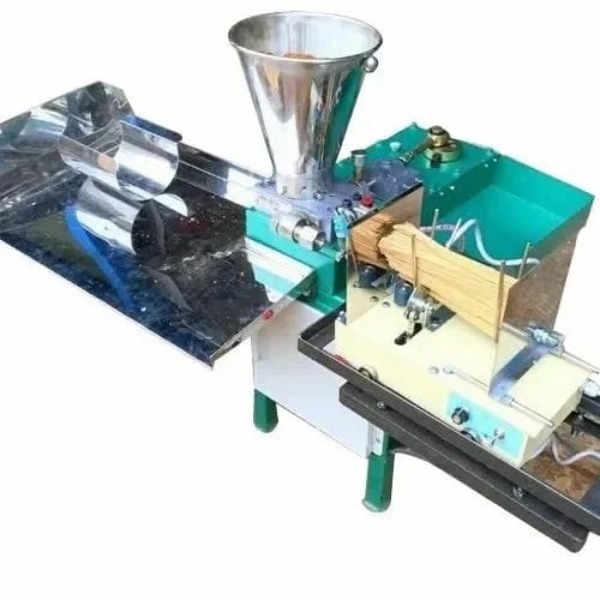

A standard high-speed automatic machine typically consists of the following:

Component Function

Stick Feeder Automatically aligns and pushes bamboo sticks into the nozzle.

Piston/Cylinder Compresses the wet masala (powder mix) onto the stick.

Pressure Control Adjusts the thickness and smoothness of the stick.

Motor Usually a 1HP or 2HP single-phase motor for energy efficiency.

PLC Control Digital interface to adjust speed and count production.

4. The Manufacturing Process

Using a machine involves a systematic workflow to ensure the final product is of high quality.

Raw Material Mixing: A blend of charcoal powder, Jigat (binder), sawdust, and water is mixed to create a dough-like 'masala.'

Feeding: The dough is placed in the machine's cylinder, and bamboo sticks are loaded into the hopper.

Extrusion: The machine applies the paste onto the sticks through a nozzle.

Drying: The 'raw' sticks are spread on trays and dried (sun-dried or using a dryer machine).

Scenting: Once dry, the sticks are dipped into a mixture of diethyl phthalate (DEP) and concentrated perfume oils.

Packaging: The finished sticks are weighed and packed into pouches or boxes.

5. Key Advantages of Using a Machine

Investing in automation offers several strategic benefits:

Consistency: Every stick has the same diameter, which is crucial for burning time and brand reputation.

Waste Reduction: Precision engineering ensures that the 'masala' is used efficiently with minimal spill.

Scalability: A single operator can manage 2–3 machines simultaneously, allowing you to scale output without a massive increase in staff.

Versatility: Most machines can produce different sizes (8', 9', or 12') by simply changing the nozzle and stick feeder settings.

6. Maintenance Tips for Longevity

To keep your Agarbatti machine running at peak performance, follow these steps:

Daily Cleaning: Remove leftover masala from the cylinder and nozzle after every shift to prevent hardening.

Lubrication: Oil the moving parts (gears and pistons) daily to reduce friction.

Stick Quality: Use high-quality, straight bamboo sticks. Curved or damp sticks can cause the feeder to jam.

Voltage Stabilization: Use a stabilizer to protect the motor and PLC from power surges.

7. Business Outlook & Profitability

The Agarbatti business is one of the most stable 'FMCG' (Fast Moving Consumer Goods) sectors.

Pro Tip: While the machine handles the production, the real profit lies in the fragrance. Developing a unique signature scent is what builds brand loyalty.

Estimated Costs

Machine Cost: Ranges from $500 (Basic) to $3, 000+ (High-speed multi-feeder).

Raw Materials: Charcoal, Bamboo sticks, and Perfume are the primary recurring costs.

Profit Margins: Typically range between 15% to 25%, depending on your branding and distribution network.

8. Conclusion

The Agarbatti making machine has democratized the incense industry, allowing small entrepreneurs to compete with larger brands through efficiency and quality. Whether you are looking to start a small home business or a large-scale factory, choosing a reliable, high-speed automatic machine is the first step toward success.