The Agarbatti (incense stick) industry has evolved from a traditional cottage craft into a highly mechanized sector. With the global demand for fragrance products rising, the Agarbatti Making Machine has become the backbone of modern production, allowing manufacturers to scale up while maintaining consistent quality.

The Shift from Manual to Machine

Traditionally, incense sticks were hand-rolled, a process that was labor-intensive and resulted in variations in thickness and burning time. Modern machines have revolutionized this by automating the application of the 'masala' (a mixture of charcoal powder, Jigat powder, and aromatic ingredients) onto the bamboo sticks.

Key Types of Agarbatti Making Machines

Depending on the scale of production, businesses usually choose from three main categories:

Manual Machines: Best for home-based startups, these require hand-pedaling but are much faster than hand-rolling.

Automatic Machines: These are the industry standard. They feed bamboo sticks automatically and can produce between 150 to 300 sticks per minute.

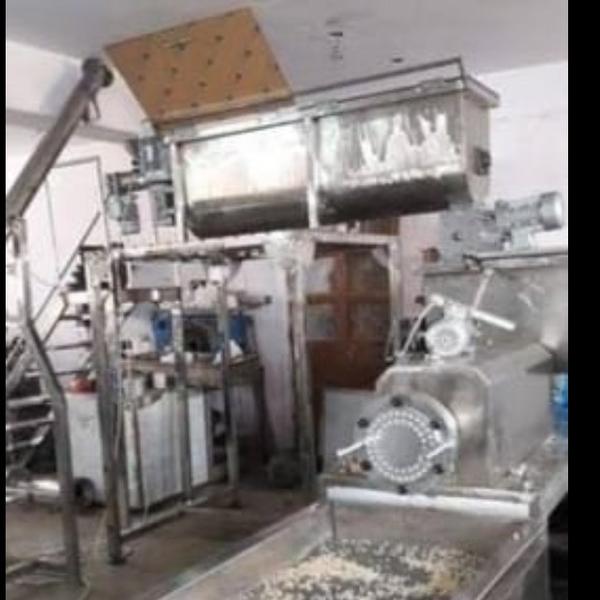

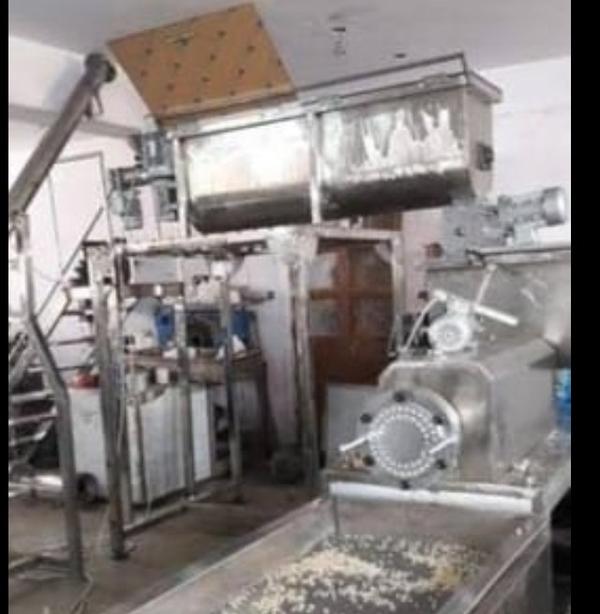

High-Speed Fully Automatic Machines: Designed for large-scale factories, these can exceed 400 sticks per minute and often include integrated drying systems.

Technical Features and Components

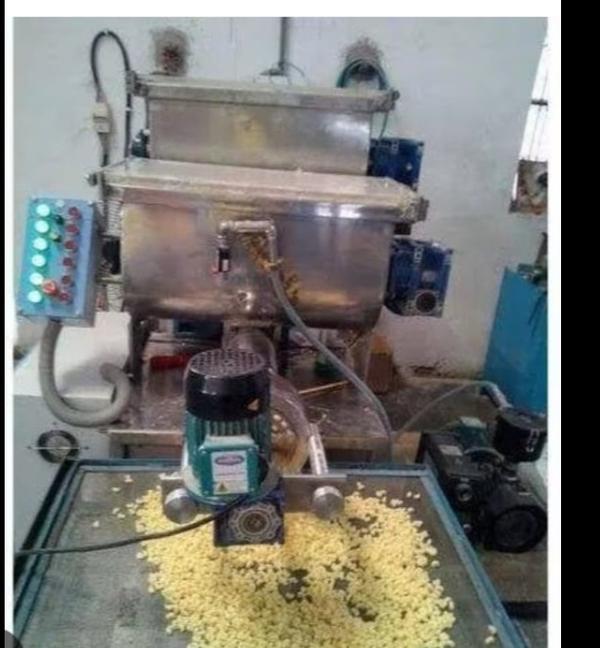

A standard automatic machine consists of several critical parts that ensure a smooth workflow:

Hopper: Holds the raw powder mix.

Feeder Assembly: Automatically pushes the bamboo sticks into the coating chamber.

Piston/Die System: Extrudes the paste onto the stick with uniform pressure.

Control Panel: Allows the operator to adjust speed, length, and pressure.

Most modern machines are designed with heavy-duty MS (Mild Steel) frames to reduce vibration, ensuring that the sticks come out straight and uniform.

Advantages of Using Machines

1. High Productivity

A single automatic machine can do the work of 10 to 15 manual laborers. This high output is essential for meeting bulk orders and seasonal demands (such as during festivals).

2. Consistency and Quality

Machines ensure that every stick has the exact same diameter and weight. This uniformity is crucial for packaging, as it ensures the sticks fit perfectly into boxes and burn for a predictable amount of time.

3. Waste Reduction

Manual rolling often results in significant powder wastage. Machines are calibrated to use the precise amount of raw material required, significantly lowering the cost of production per unit.

4. Low Maintenance

Modern Agarbatti machines are built for durability. With regular oiling and cleaning of the die and piston, these machines can run for years with minimal downtime.

Business Potential and ROI

The Agarbatti business is considered a 'recession-proof' industry because incense is used daily in many cultures for religious, spiritual, and aesthetic purposes.

Low Entry Barrier: You can start a small unit with just one machine in a 10x10 room.

Profit Margins: By automating, you reduce labor costs, which are the highest recurring expense in manual units.

Diversification: The same machine can often produce different sizes (8-inch, 9-inch, or 12-inch) by simply changing the die.

Conclusion

The Agarbatti making machine is a game-changer for entrepreneurs looking to enter the FMCG (Fast Moving Consumer Goods) sector. It transforms a slow, artisanal process into a streamlined, profitable venture. As the market for organic and premium fragrances grows, having the right machinery ensures you can keep up with quality standards and high-volume demands.