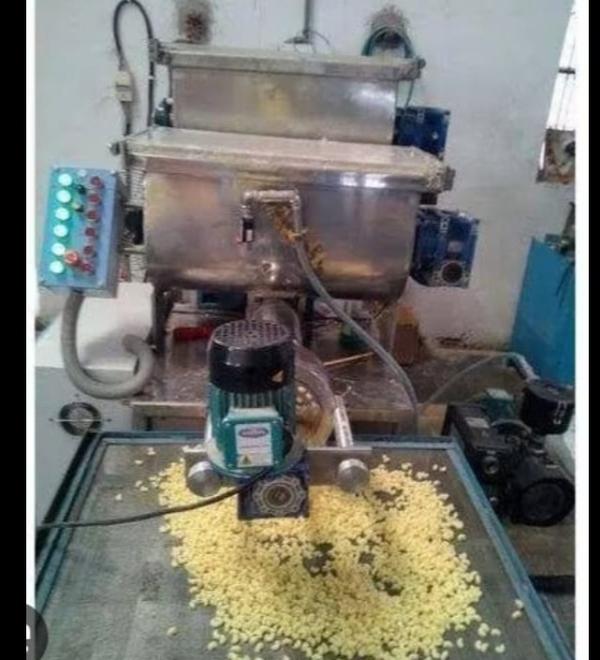

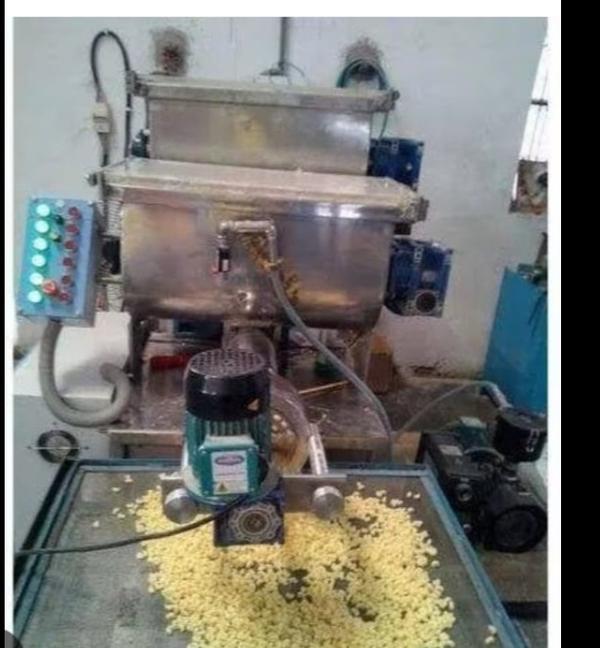

The production of macaroni at scale is a fascinating blend of culinary tradition and high-tech engineering. Whether you’re looking to start a small boutique pasta brand or an industrial-scale facility, understanding the mechanics of a Macaroni Pasta Making Machine is essential.Below is a comprehensive guide to the technology, processes, and types of machinery involved in transforming simple flour into the tubular pasta we all love.1. Introduction to Pasta Extrusion TechnologyAt its core, a macaroni machine is an extruder. Unlike handmade pasta that is rolled and cut, macaroni requires pressure to form its signature hollow shape. Modern machines are designed to handle everything from mixing the raw ingredients to the final drying stage, ensuring consistency in texture, color, and shelf-life.2. Key Components of the MachineA professional macaroni making line is rarely a single 'box.' It is a series of integrated components:The Mixer/Dosing System: This is where semolina (durum wheat flour) and water are combined. High-end machines often feature vacuum mixing technology to eliminate air bubbles, resulting in a more translucent, stronger pasta.The Extrusion Screw: The 'heart' of the machine. This large screw pushes the dough through the barrel toward the die.The Die (Molding Plate): A bronze or Teflon-coated plate with specific holes. For macaroni, the die has a 'pin' in the center of each hole to create the hollow tube.The Cutting System: A rotating blade at the face of the die that determines the length of the macaroni (e.g., short-cut elbow macaroni vs. longer tubes).The Pre-Dryer (Shaker): Immediately after cutting, the pasta is vibrated and hit with hot air to prevent the pieces from sticking together.3. The Step-by-Step Production ProcessA. Raw Material PreparationQuality macaroni starts with Semolina. The machine’s dosing system ensures a precise ratio—typically 100 kg of flour to about 25–30 liters of water.B. Vacuum ExtrusionThis is the most critical technical phase. By removing oxygen during the mixing and pressing phase, the machine prevents the oxidation of carotenoids (the pigments that give pasta its yellow color). This results in a bright, appetizing product rather than a dull, greyish one.C. Shaping and CuttingAs the dough is forced through the die at high pressure, the speed of the rotating cutter determines the shape.Bronze Dies: Create a rougher surface, which is excellent for 'holding' sauce—often preferred for premium brands.Teflon Dies: Create a smooth, shiny surface and are generally faster to clean.D. Drying (The Longest Step)Freshly extruded macaroni has a moisture content of about 30%. To make it shelf-stable, it must be dried to below 12.5%.Trabatto (Pre-drying): Quick surface drying.Main Drying Room: The pasta travels through a multi-tier conveyor in a temperature-controlled environment for several hours.4. Types of Macaroni MachinesMachine TypeCapacityBest ForManual/Semi-Auto5–15 kg/hrSmall restaurants, labs, or home businesses.Single-Screw Extruder50–200 kg/hrMedium-sized enterprises (SMEs).Twin-Screw Extruder500+ kg/hrLarge-scale industrial production; highly efficient.Fully Automatic LineUp to 2000 kg/hrMass-market supply with integrated packaging.5. Technical Specifications to ConsiderWhen shopping for or designing a machine, keep these variables in mind:Pressure Rating: Higher pressure often translates to a denser, higher-quality pasta.Cooling System: Extrusion generates heat. A water-cooling jacket around the barrel is necessary to keep the dough from 'cooking' before it exits the die.Stainless Steel Grade: Food-grade SS304 or SS316 is non-negotiable for hygiene and longevity.Automation (PLC): Modern machines use Programmable Logic Controllers to manage temperature, humidity, and motor speeds from a single touchscreen.6. Maintenance and HygieneBecause pasta dough is organic and moist, it is a breeding ground for bacteria if the machine isn't cleaned properly.CIP (Clean-In-Place): Many industrial machines feature easy-access ports to wash the internal screw and barrel.Die Cleaning: Dies must be soaked in ultrasonic cleaners or specialized water baths to remove hardened dough from the intricate holes.7. The Business Case: Why Invest?The global pasta market is incredibly resilient. Macaroni is a staple 'comfort food' with a long shelf life, making it easy to transport and export. With a versatile machine, you aren't limited to just macaroni; by simply changing the die, the same machine can produce fusilli, penne, or shells.Pro Tip: Look for machines that offer 'energy recovery systems' in the drying phase. Drying accounts for nearly 70% of the energy cost in pasta production, so efficiency here is the key to profitability.