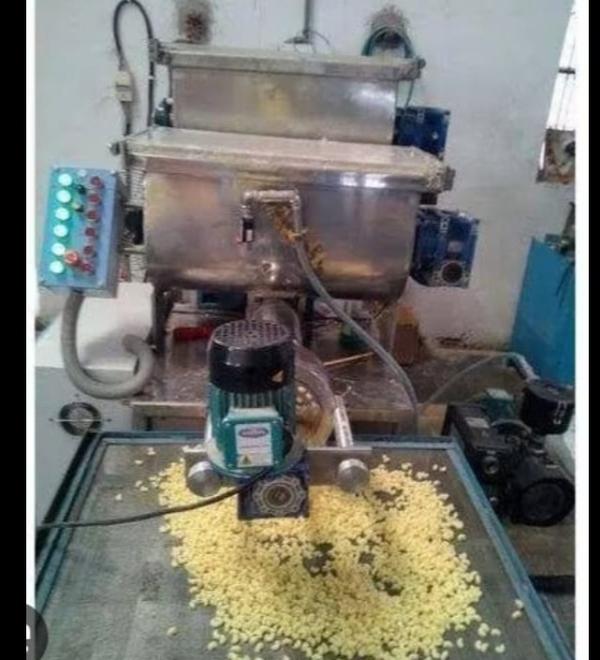

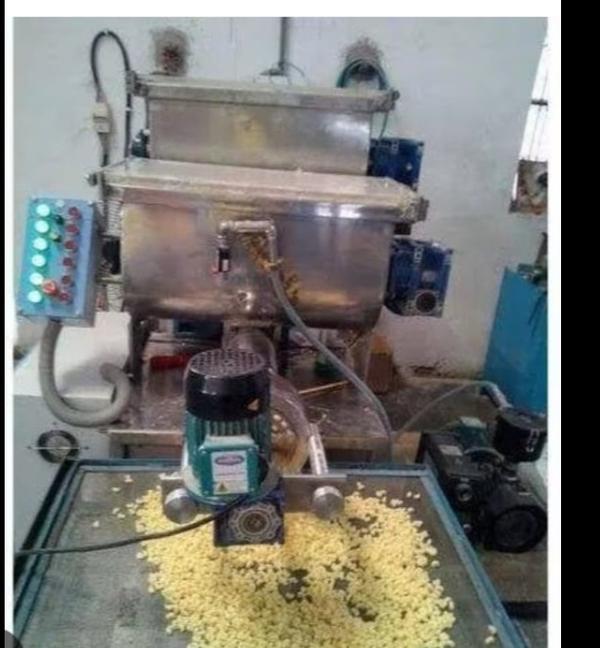

The Agarbatti (incense stick) industry is a cornerstone of the global fragrance and spiritual market. Traditionally a labor-intensive, hand-rolled craft, the industry has undergone a massive transformation through automation.If you are looking to start a business or upgrade your production, understanding the mechanics, types, and economic benefits of Agarbatti Making Machines is essential. Here is a comprehensive guide to everything you need to know.1. The Evolution: From Hand-Rolled to High-TechFor centuries, incense sticks were made by hand, where a paste of charcoal, sawdust, and fragrance was rolled onto bamboo sticks. While artisanal, this method limited production speed and consistency.Modern machines have revolutionized this by introducing high-speed extrusion. Today’s machines can produce anywhere from 150 to 450 sticks per minute, ensuring every stick is uniform in thickness, length, and burning time.2. Types of Agarbatti Making MachinesChoosing the right machine depends on your budget, space, and target production volume.Machine TypeProduction SpeedBest For...Manual Machine50-80 sticks/minHome-based startups and small cottage industries.Automatic Machine150-250 sticks/minSmall to medium enterprises (SMEs).High-Speed Automatic300-450+ sticks/minLarge-scale industrial production.Powder Mixing MachineN/AEssential for preparing the raw material dough.Drying MachineN/AUsed in humid climates to ensure moisture-free sticks.Automatic Agarbatti MachinesThese are the industry standard. They feature a hopper for the powder mix and a feeder for the bamboo sticks. The machine automatically applies the paste to the stick and ejects the finished product. They are prized for their low maintenance and easy operation.3. Key Components of the MachineTo maintain your machine effectively, you need to understand its 'anatomy':Piston/Cylinder: The heart of the machine that pushes the wet powder through the die.Die: The mold that determines the diameter of the incense stick.Stick Feeder: An automated tray that ensures bamboo sticks are fed into the machine at the perfect rhythm.PLC Control Panel: Found in high-end models, this allows you to adjust speed and monitor production counts.Motor: Usually ranging from 1HP to 2HP, providing the necessary torque for heavy-duty extrusion.4. The Production ProcessRunning an Agarbatti making machine involves a simple, repeatable workflow:Raw Material Preparation: Mixing charcoal powder, Jigat (binder), sawdust, and water in a ribbon blender to create a semi-solid dough.Feeding: Loading the bamboo sticks into the feeder and the dough into the machine's hopper.Extrusion: The machine coats the sticks with the paste.Drying: The 'raw' sticks are laid out on trays to dry. This can be done naturally in the sun or via a drying machine.Scenting (Perfuming): Once dry, the sticks are dipped in a mixture of aromatic chemicals and DEP (Diethyl Phthalate).Packaging: The final sticks are counted, weighed, and packed into boxes or pouches.5. Why Invest in an Automatic Machine?If you're on the fence about automation, consider these advantages:Consistency: Every stick looks identical. In the fragrance market, branding and 'look' are everything.Reduced Labor Costs: One operator can manage two or even three automatic machines simultaneously.Waste Reduction: Modern machines are designed to minimize 'coning' (uneven coating) and powder wastage.Scalability: It is much easier to double your output by adding another machine than by hiring and training ten more manual rollers.6. Maintenance and LongevityTo ensure your machine lasts for 10+ years, follow these golden rules:Daily Cleaning: The 'Jigat' binder is sticky. If left overnight, it hardens and can jam the piston. Always clean the hopper and die after every shift.Lubrication: Oil the moving parts and gears weekly to prevent friction-related wear and tear.Stick Quality: Only use high-quality, straight bamboo sticks. Curved or 'burred' sticks are the #1 cause of machine jams.7. Business Outlook and ROIThe Agarbatti business is considered 'recession-proof' because incense is used daily in religious rituals, aromatherapy, and homes for fragrance.The Math (Estimated):An automatic machine producing 100kg of sticks per day can typically generate a profit margin of 15% to 25% after raw material and electricity costs. Most entrepreneurs see a Return on Investment (ROI) within 8 to 14 months of operation, depending on their marketing reach.Pro Tip: Don't just sell 'incense.' Sell an experience. Focus on unique scents like Oudh, Sandalwood, or Lemongrass to stand out from the competition.