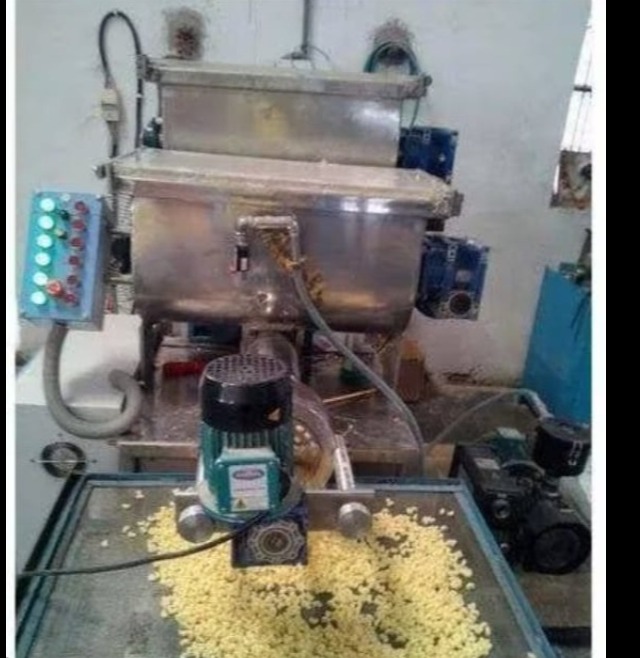

If you’re looking to dive into the world of industrial food production or simply curious about how that perfectly ridged penne ends up in your bowl, you’ve come to the right place.Building a high-capacity pasta production line is a blend of culinary art and heavy-duty engineering. Here is a deep dive into the mechanics, the process, and the business logic of Macaroni Pasta Making Machines.1. The Anatomy of a Professional Pasta MachineAt its core, an industrial macaroni machine isn't just a big mixer; it is a pressurized extrusion system. Unlike handmade pasta, which relies on rolling and cutting, commercial macaroni is extruded—pushed through a die under immense pressure to create specific shapes.Key Components:The Vacuum Mixer: This is where the magic starts. By mixing semolina flour and water under a vacuum, the machine prevents air bubbles from forming. This results in a denser, clearer pasta with a better 'snap' and longer shelf life.The Extrusion Screw: Often made of stainless steel or high-grade alloys, this screw pushes the dough forward.The Cooling System: Extrusion creates friction, which creates heat. If the dough gets too hot, it cooks the protein prematurely. High-end machines use water-cooling jackets to keep the dough at a stable temperature.The Die (The Shape-Maker): These are usually bronze or Teflon-coated.Bronze Dies create a rougher surface, which is 'premium' because it helps sauce stick to the pasta.Teflon Dies create a smooth, shiny pasta that moves through the machine faster.2. The Production Process: From Flour to ForkCreating macaroni is a linear process that requires precise timing. If one stage fails, the entire batch is compromised.Step 1: Dosing and MixingThe machine automatically calculates the ratio of semolina to water (and sometimes eggs or spinach puree). The goal is a moisture content of roughly 25% to 30%. It shouldn't look like bread dough; it should look like moist, crumbly sand.Step 2: ExtrusionAs the screw rotates, it compresses the crumbles into a solid mass. It is forced through the die. A rotating blade at the end of the die spins at a specific speed—this determines the length of the macaroni. Spin it fast for short elbows; spin it slow for long rigatoni.Step 3: Pre-Drying (The 'Shaker')Fresh pasta is sticky. To prevent it from clumping, it immediately enters a 'vibratory pre-dryer.' This shakes the pasta while hitting it with hot air to create a 'skin' on the outside.Step 4: The Drying TunnelThis is the most critical stage. Pasta must be dried slowly. If you dry it too fast, it cracks (checking). If you dry it too slow, it can mold.Industrial drying can take anywhere from 6 to 24 hours depending on the thickness.3. Types of Macaroni MachinesDepending on your scale, you’ll fall into one of three categories:Machine TypeCapacityBest ForCountertop Extruders5–15 kg/hrSmall bistros and boutique shops.Medium-Scale Lines30–100 kg/hrRegional suppliers and supermarkets.Industrial Lines500+ kg/hrNational brands and export-level production.4. Why Invest in an Automatic Line?If you're weighing the pros and cons of 'going big' with an automated macaroni machine, consider these factors:Consistency is KingA machine doesn't have a 'bad day.' Once you program the pressure ($P$) and the hydration levels, every single elbow macaroni will be identical in weight, texture, and cooking time.VersatilityYou aren't stuck with just macaroni. By simply swapping the die head, the same machine can produce:Fusilli (spirals)Penne (tubes)Conchiglie (shells)Farfalle (bowties - though these often require an additional shaping unit)Hygiene and ComplianceModern machines are designed with CIP (Clean-In-Place) capabilities. Stainless steel construction ensures that the line meets FDA or CE safety standards, reducing the risk of bacterial contamination.5. Maintenance and LongevityThese machines are 'workhorses, ' but they aren't 'set it and forget it.'Die Cleaning: After every run, dies must be soaked in ultrasonic baths to remove every trace of dough. Dried dough in a die can ruin the next batch's shape.Lubrication: The high-pressure gearboxes require food-grade lubricants.Blade Sharpening: The cutter blade must be razor-sharp to ensure a clean 'clip' on the macaroni. A dull blade squashes the ends of the pasta, closing the hole.6. Future Trends: The 'Green' Pasta MachineThe industry is shifting toward sustainability. Newer models focus on:Energy Recovery: Capturing the heat from the drying process to pre-heat the mixing water.Alternative Flours: Machines are being recalibrated to handle gluten-free flours (rice, lentil, chickpea), which have different binding properties than traditional wheat.Summary Checklist for BuyersIf you are looking to purchase a machine, keep these three specs at the top of your list:Motor Power: Is it beefy enough to handle thick, low-moisture dough?Vacuum Capability: Does it have a built-in vacuum pump for airless mixing?Drying Integration: Does the machine come with a drying solution, or do you need to buy racks and fans separately?