The Ultimate Guide to Agarbatti Making Machines: Industry, Technology, and Business Growth

The incense stick (Agarbatti) industry is one of the oldest and most consistent sectors in the global market, particularly in Southeast Asia. Traditionally a manual craft, the industry has undergone a massive transformation through automation.1 The Agarbatti Making Machine has become the backbone of this evolution, allowing small-scale entrepreneurs and large manufacturers alike to meet the rising global demand for aromatic products.

This guide explores the types of machines available, the technical process, and how to choose the right equipment for a successful business.

1. The Shift from Manual to Machine Production

For centuries, Agarbatti was made by hand-rolling a paste of charcoal, sawdust, and fragrance onto bamboo sticks. While artisanal, this method was slow, inconsistent, and difficult to scale.

Modern machines offer three primary advantages:

Consistency: Every stick has the same thickness and length, ensuring a uniform burn time.2

Speed: A single high-speed machine can produce as many sticks as 20–30 manual laborers.

Waste Reduction: Precision feeding mechanisms ensure minimal raw material loss.3

2. Types of Agarbatti Making Machines

Choosing the right machine depends on your budget, production goals, and available space.

A. Manual Hand-Operated Machines

Best for hobbyists or very small cottage industries. These require a foot pedal or hand lever to push the paste onto the stick.4

Pros: Low cost, no electricity needed.5

Cons: Low output, physically demanding.6

B. Semi-Automatic Machines

In these models, the machine applies the paste, but the operator must manually feed the bamboo sticks into the feeder.

Pros: Affordable for startups.

Cons: Requires constant human intervention; slower than fully automatic models.

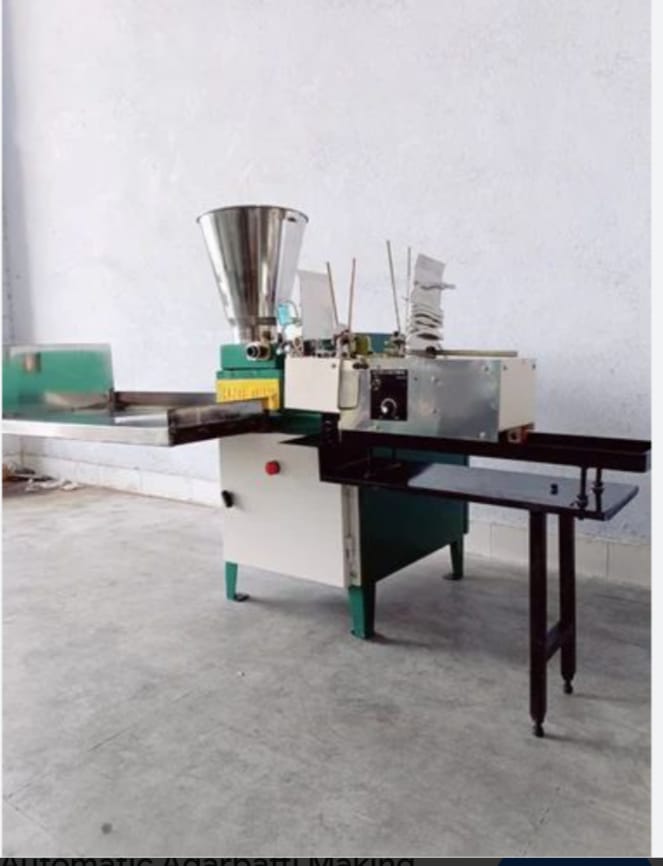

C. Fully Automatic High-Speed Machines

This is the industry standard for commercial production. These machines feature an automatic stick feeder and a sensor-based system.7

Production Capacity: Ranges from 150 to 450 sticks per minute.

Features: Often equipped with PLC (Programmable Logic Controller) systems to adjust speed and stick length.8

D. Incense Cone & Dhoop Machines

While standard machines make sticks, specialized hydraulic machines are used to create Dhoop sticks (stickless incense) and cones.9 These use high-pressure compression rather than an extrusion process over a bamboo core.

3. Key Components of the Machine

Understanding the "anatomy" of your machine helps in maintenance and troubleshooting:

| Component | Function |

| Hopper | Where the wet raw material (masala) is loaded. |

| Stick Feeder | A vibrating tray that aligns and feeds bamboo sticks one by one. |

| Piston/Die | The heart of the machine that extrudes the paste onto the stick. |

| Control Panel | Allows the user to toggle power, speed, and emergency stops. |

| Collection Tray | Where the finished wet sticks are gathered before drying. |

4. The Production Process: Step-by-Step

Using a machine isn't just about pressing a button; it involves a systematic workflow:

Step 1: Raw Material Mixing

A "Dry Mixer" machine is used to blend charcoal powder, Jigat (binder), sawdust, and water. The consistency must be like soft dough—not too dry (or it won't stick) and not too wet (or it will clog the machine).

Step 2: Extrusion (The Machine Phase)

The mixture is loaded into the hopper.10 The automatic feeder pushes a bamboo stick through the die precisely as the piston compresses the paste around it.

Step 3: Drying

Wet sticks cannot be packed immediately. They are spread on wooden trays and dried.

Natural Drying: Takes 24–48 hours depending on humidity.

Drying Machine: Specialized ovens can dry sticks in a few hours, ensuring they don't warp or catch mold.

Step 4: Scenting (Dipping)

Once dry, the "raw" sticks are dipped into a mixture of Fragrance Oil and DEP (Diethyl Phthalate). The ratio is typically 1:3 or 1:4.

Step 5: Packaging

The final product is counted and packed into pouches or boxes using an Automatic Pouch Packing Machine.

5. Technical Specifications to Consider

If you are looking to purchase a machine, look for these standard specs:

Motor Power: Usually 11$1.0 HP$ to 12$2.0 HP$, Single Phase.13

Production Rate: Look for at least 300 sticks/minute for profitability.

Stick Diameter: Most machines support $2.1 mm$ to $3.5 mm$ sticks.

Machine Weight: Heavier machines (100kg+) tend to vibrate less, leading to better precision.

6. Maintenance and Longevity

To ensure your machine lasts 10–15 years, follow these maintenance tips:

Daily Cleaning: Remove all leftover paste from the hopper and die at the end of the shift. Hardened paste can damage the piston.

Lubrication: Oil the moving gears and the piston daily.14

Sensor Check: Keep the infrared sensors clean of dust to ensure the stick feeder doesn't miss a beat.

7. Business Feasibility and ROI

Starting an Agarbatti business with a machine is considered a "Low Investment, High Return" venture.15

Market Demand: Used daily in homes, temples, and offices for meditation and air purification.16

Scalability: You can start with one machine in a 10x10 room and add more as your brand grows.

Export Potential: There is a massive demand for Indian and Asian incense in the US, Europe, and UAE.

Pro Tip: Don't just sell "Raw Sticks." The real profit lies in the Branding and Fragrance. Selling a finished, packaged product can increase your profit margins by 40% compared to selling wholesale raw sticks.

8. Conclusion

The Agarbatti making machine is a game-changer for small entrepreneurs. It turns a labor-intensive process into a streamlined industrial operation.17 By selecting a high-quality fully automatic machine and focusing on unique fragrance blends, you can establish a stable, recession-proof business.