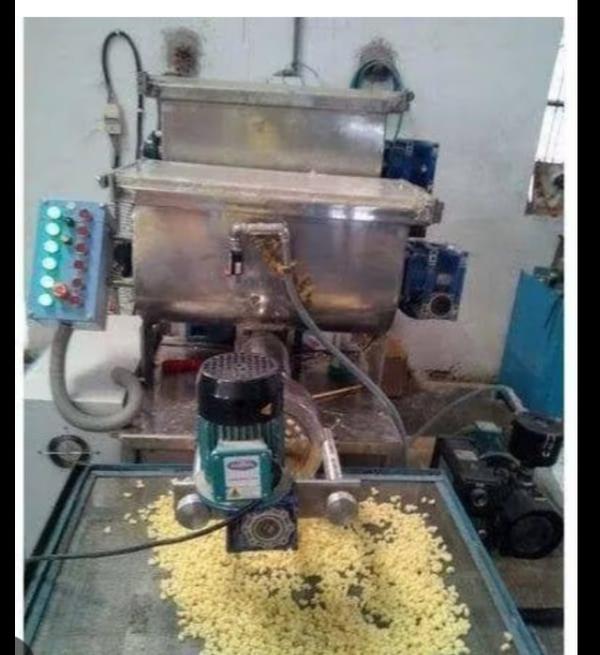

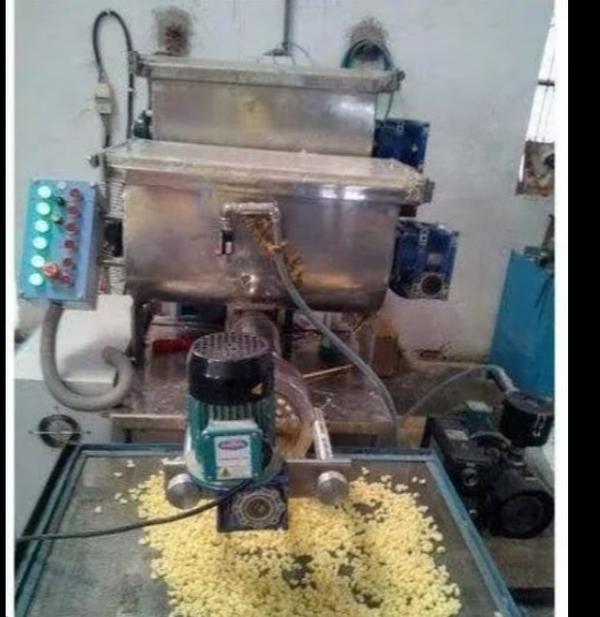

Whether you are an aspiring entrepreneur looking to enter the food industry or a seasoned manufacturer upgrading your line, understanding the mechanics and benefits of a Pasta Macaroni Making Machine is essential. This guide breaks down everything from the technical process to the business advantages of industrial pasta production.1. Introduction to Macaroni ProductionPasta remains a global staple due to its long shelf life, ease of preparation, and high nutritional value. Modern macaroni making machines have evolved from manual presses to fully automated extrusion systems capable of producing hundreds of kilograms per hour with minimal human intervention.+1The core technology behind these machines is Single-Screw or Twin-Screw Extrusion, which allows for precise control over the texture, shape, and density of the pasta.2. How the Machine Works: The Production ProcessThe journey from raw flour to a packaged box of macaroni involves several sophisticated stages:A. Raw Material MixingThe process begins with the Mixer. Here, semolina flour (or wheat flour) is mixed with water and sometimes additives like eggs, vegetable purees (spinach or tomato), or vitamins.Goal: To achieve a uniform moisture content, usually around 25% to 30%.B. Extrusion (The Heart of the Machine)The mixed dough enters the Extruder. Inside, a screw conveys the dough through a pressurized barrel.The Die Head: At the end of the barrel is a 'die'—a metal plate with holes shaped like elbows, shells, or spirals.Cutting: As the pasta emerges from the die, a high-speed rotary cutter snips the dough to the desired length.C. Pre-Drying and CoolingFreshly extruded pasta is soft and sticky. It passes through a Pre-dryer (shaker) to prevent the pieces from sticking together and to begin the surface-hardening process.D. Continuous DryingThis is the most critical stage. The pasta enters a multi-layer drying oven.Objective: To reduce moisture content from approx. 30% to 12%.Precision: If dried too fast, the pasta cracks; if too slow, it can spoil. Modern machines use PLC (Programmable Logic Controller) systems to manage temperature and humidity perfectly.+13. Technical Specifications to ConsiderWhen shopping for a macaroni machine, the 'best' model depends on your output goals.FeatureSmall-Scale / StartupIndustrial / Large-ScaleProduction Capacity30 – 100 kg/h200 – 1, 000+ kg/hPower Consumption15 – 30 kW60 – 150+ kWMaterialFood-grade Stainless SteelFood-grade Stainless SteelAutomationSemi-AutomaticFully Automated (PLC)Space Required50 – 100 sq. meters200+ sq. meters4. Key Advantages of Industrial Macaroni MachinesShape Versatility: By simply changing the die head, one machine can produce macaroni, fusilli, penne, shells, and even 3D novelty shapes.Consistency: Automation ensures that every piece of pasta has the same thickness and cooking time, which is vital for brand reputation.High Efficiency: Modern extruders use vacuum technology to remove air bubbles, resulting in a 'clearer' pasta that doesn't break easily during boiling.Labor Savings: A fully automated line requires only 2 or 3 operators to oversee the entire process from mixing to packaging.5. Maintenance and HygieneSince pasta involves flour and water, hygiene is paramount.Easy Clean-up: Look for machines with 'CIP' (Clean-In-Place) features or those made of SUS304 Stainless Steel to prevent rust and bacterial buildup.Lubrication: Regular maintenance of the vacuum pump and the extrusion screw ensures the machine can run for 24-hour shifts without overheating.6. Business Outlook: Why Invest?The global pasta market is projected to continue growing, driven by the demand for 'convenience foods' and the rise of healthy, whole-grain, or gluten-free pasta variants.Low Raw Material Cost: The primary ingredients (flour and water) are relatively inexpensive.High Value-Add: The margin between raw flour prices and packaged macaroni prices is significant.Shelf Stability: Dried macaroni can be stored for 1–2 years, reducing the risk of inventory loss.ConclusionInvesting in a Pasta Macaroni Making Machine is not just about buying hardware; it’s about mastering the science of extrusion. Whether you are targeting local grocery stores or international exports, the right machine ensures your product stands out in texture, appearance, and taste.